|

|

Interview with Takuya Nakamura, President of TNK Sanwa Precision Co., Ltd.

Takuya Nakamura, President of TNK Sanwa Precision Co., Ltd.

Takuya Nakamura

President of TNK Sanwa Precision Co., Ltd.

TNK Sanwa Precision Co., Ltd. was established in 1946 under the name Tanaka Mfg. in Tokyo. TNK Sanwa Precision Co., Ltd. has focused on the production of high precision roller, needle and micro shaft for industrial machinery, automotive market and small diameter sliding screw for robot market. Based on the company’s philosophy of creating things with technology and quality, TNK Sanwa Precision Co., Ltd. has expanded its networks domestically and globally. We had an interview with Takuya Nakamura as the president of the company, to deeper discuss the company and its strategies globally.

Japanese companies have always been known for providing high-quality products. How do you think Japanese companies able to compete with Chinese companies with lower manufacturing costs in terms of sales?

Japanese and Chinese companies both have different markets. Japanese superiority is high-quality products, while Chinese superiority is low-cost. Our Chinese factory produce by Japanese high-quality and supply by Chinese low-cost to respond to Chinese low-cost market.

TNK Sanwa Precision Co., Ltd. focuses on producing high-quality products, what are your technologies used in the manufacturing processes of these products?

Products undergo several processes and treatments with sets of developed machines. (Processes: Turning, Grinding, Heat-treatment, Stamping, Molding, Polishing, Forging, cutting, Assembly) Each process creates high-quality parts which are then combined in creating a product. The biggest challenge in making high-quality products is during the grinding process. Grinding machines are very difficult to set and only special skilled people can operate this machine to create high-quality results. We are sure that the collaboration of special-skills people and developed original machines are the strategies we implement in creating high-quality products to the several market companies in the world.

What is TNK Sanwa Precision Co., Ltd.’s main target industry for these high-quality products?

Our main targets are carmakers, with 60% of our sales are contributed by Japanese Tier 1 maker as our main clients. From now on we would like to make a business with western Tier 1 maker. We have a business with Japanese industrial machinery makers also. This market requirement is high-quality of needle and roller. We would like to make a business with western industrial machinery makers by our high-quality parts.

Which business sector do you think has the most potential in terms of growth of TNK Sanwa Precision Co., Ltd.’s as a company?

As a company, we are always concentrating on our business growth. We think that the medical equipment industry is a potential sector for us to penetrate. In the medical equipment industry, machines for operation is very important in assisting doctors. These machines help doctors to reach out to sensitive parts that need precision. Although these machines are not advanced enough to do those things, we believe that shortly, our machines are ready to play an important role in the medical sectors after 5G coming. Our target is to produce this machine with high precision one day and we have started to introduce this machine to universities and other research facilities.

Through producing high precision technology in two factories, including in China, how does it allow TNK Sanwa Precision Co., Ltd. to expand the market and create a competitive advantage?

As a Japanese company that operates a factory in China, it creates certain collaboration in creating efficient operation. We are uniting the Japanese skills and knowledge with Chinese low operation cost. This creates advantages in production efficiency, while still making the best output results. Japanese companies have a focus on the development of skills and mass production efficiency. Through operating a factory in China, we can manage to get the order from foreign countries to make products at a reasonable price. By doing so, we create advantages of making high-quality products at a cheaper cost to penetrate the global market.

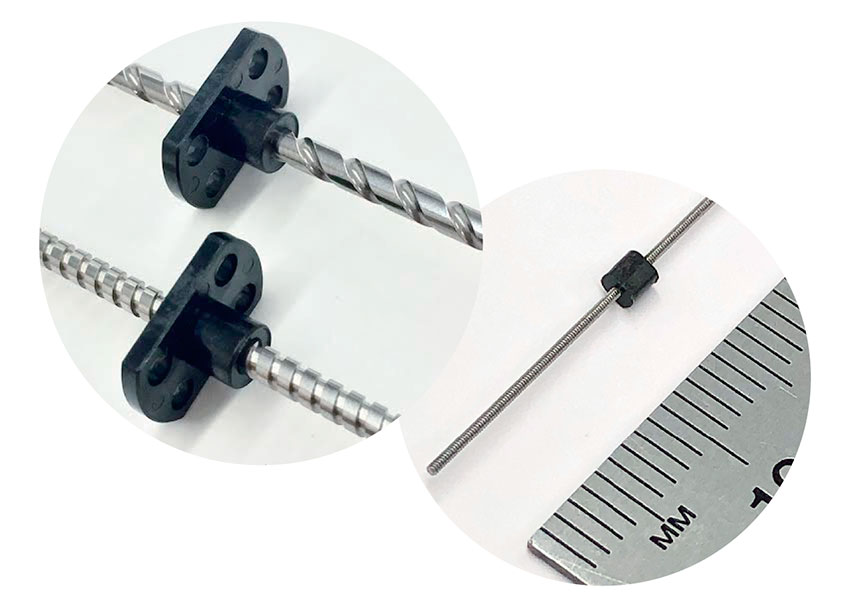

Sliding Screws

When talking about going global, what is the importance of the foreign market in TNK Sanwa Precision Co., Ltd.’s growth strategy?

Among all our sales, 60% of it is automotive-related industries with 90% of it is Japanese automotive makers. Our strategy is to get a high volume of shares in the Japanese market, in hope that the percentage can transfer to western markets. Fortunately, Japanese demand on automotive parts are similar to German and US market, and so it is easier for us to penetrate to those market as the technology is mostly similar. These strategies will help us expand our growth strategy into new markets. For western carmaker, we have get IATF16949. We would like to build up the special western sales team last 2015. Currently they have make an inspection of to join western carmaker’s exhibition. They have join Shanghai carmaker’s exhibition. Also they have renew our HP by English version.

How can the technology of creating lighter material or smaller size help TNK Sanwa Precision Co., Ltd. in following the trends?

Lighter materials are important in following the current trends in making everything lighter. We thought this is big chance for us that we have study an injection molding technology 5 years ago. Carbon Fiber Reinforced Plastics (CFRP) to be used in automation parts industries.

This year’s target is to create smaller compact parts rather than lighter material.

It is used in several industries related to the production of robots. In these industries, smaller sliding screw are better in support. The usual sliding screw in the market are usually OD 4mm size over, however, we manage to create OD 0.5mm - 4mm size screw and we are the only company that can create this as our competitive advantage and no other company can create this. Through this OD 0.5mm - 4mm size sliding screw, we can lead to the robot production market.

http://www.tnksanwa.co.jp/en/en_item/en_leadscrews.html

In the future where robots substitute humans in doing the manufacturing job, I believe that our advantage of making smaller size parts can be a huge market 10 years from now, especially in the logistics and medical industry.

As the president of the company, if we were to come back 10 years from now, what goals do you wish to accomplish for your company?

In 10 years, I want to take TNK Sanwa Precision Co., Ltd into a more global stage. As for now, our stage of production in the foreign market is low, however, I believe that our company can increase the number of sales up to 50% by getting more customers from foreign countries. We hope more understand and use our high-quality products in the world. We want to shift from only part maker into newly established robot hand maker, in 10 years to expand more in terms of profits.

|

|

|

|